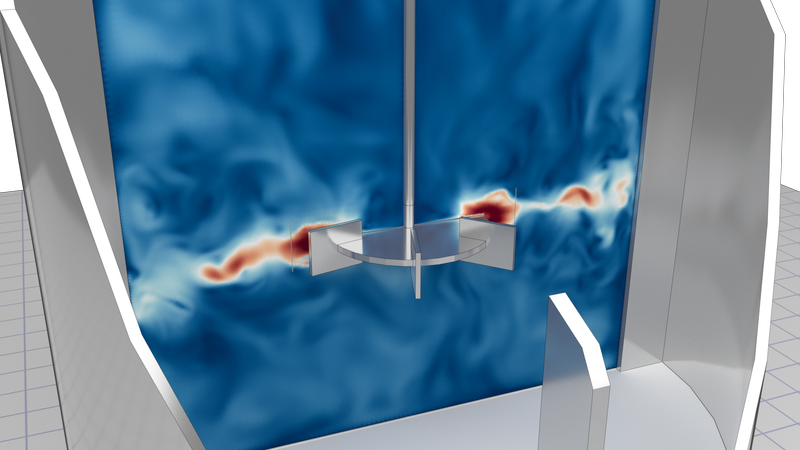

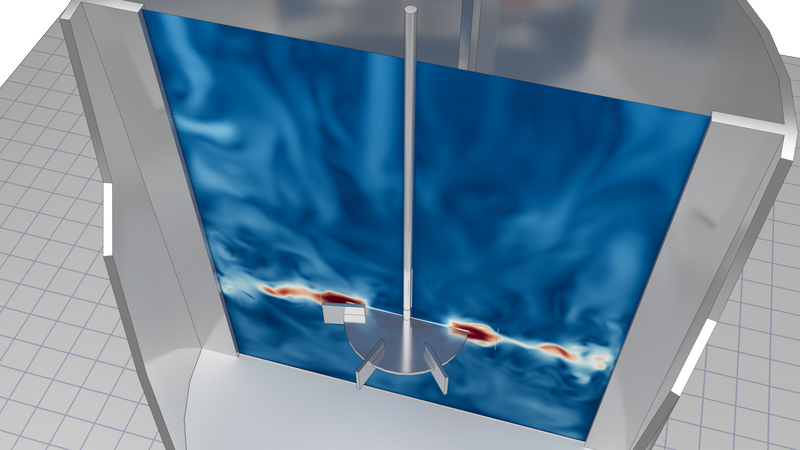

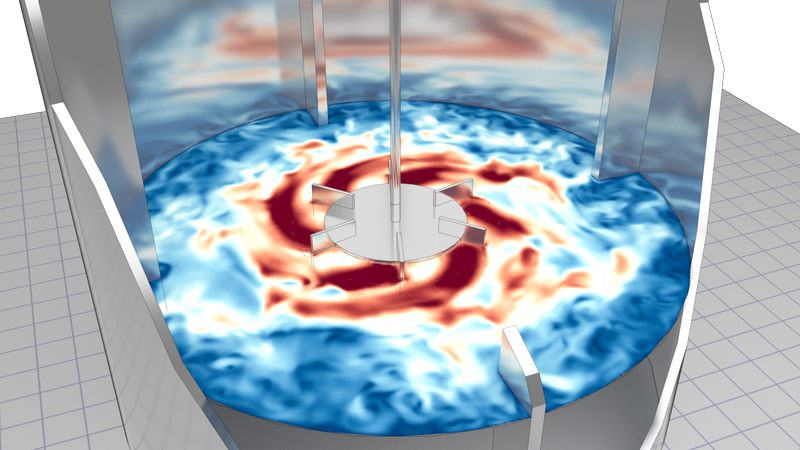

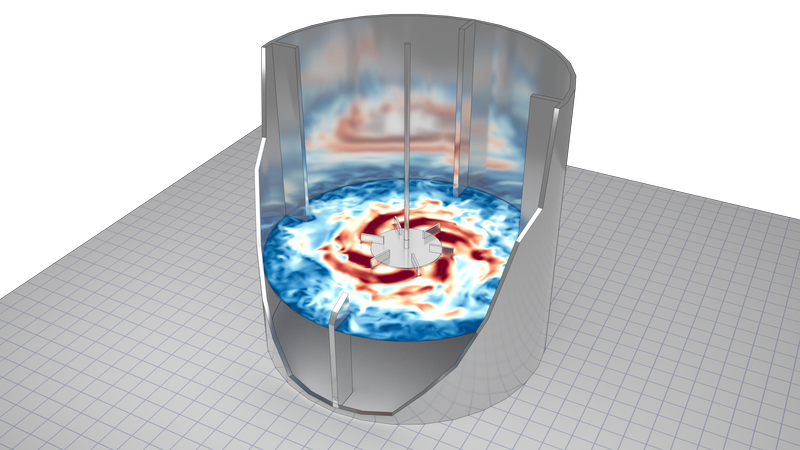

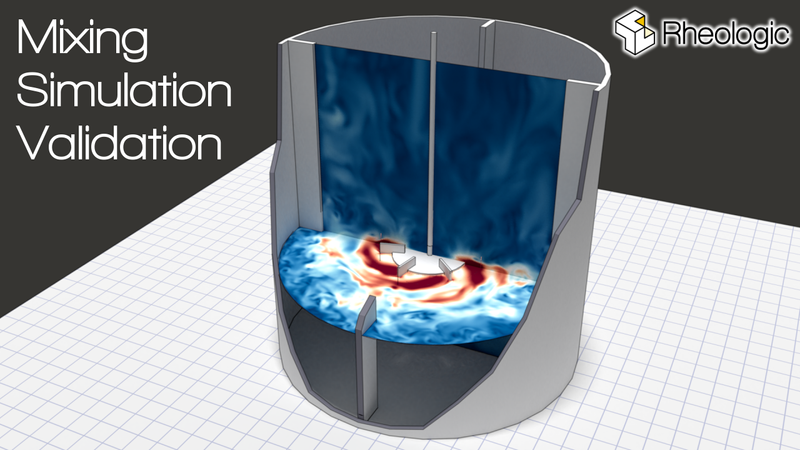

From our modest beginnings with experimental validation work, measuring the time-dependent conductivity of dissolving salt particles, we have come a long way to our current, tried and tested simulation models.

We can work with arbitrarily shaped tanks and stirrers, temperatures, densities, dissolving substances, heating, cooling and much more! Especially in industries where tests with actual formulations can be prohibitively expensive (while regulatory requirements are high), our simulations can help mitigate a lot of uncertainties within the engineering process. Our aim is to help you work on true industry 4.0 level.

What we offer:

- Liquid / liquid mixing and liquid / solid mixing with various properties (density, viscosity, ...).

- Support of batch processes, like discontinuous addition of bulk reagents.

- Heating and cooling.

- Shear stress evaluation for sensitive liquids. We can also evaluate accumulated shear stress.

- Newtonian and non-Newtonian liquids.

Whether you are fully upgrading your production, or just replacing this one old impeller that is not produced anymore - with our help, you can stay below your shear stress limit and within your mixing time!